Let’s face it: in today’s fast-moving, interconnected world, supply chain disruptions aren’t a maybe; they’re a when. From unexpected natural disasters and shifting global politics to sudden supplier failures or crippling cyberattacks, countless things can throw a wrench into your smooth flow of goods, information, and money.

Consequently, having a solid supply chain risk management plan isn’t just a “nice-to-have” for big corporations. Instead, it’s essential for any business to survive and thrive. Understanding and managing risk is key to protecting your operations and keeping your business running.

What Exactly is Supply Chain Risk? Let’s Break It Down

So, what are we talking about when we say “supply chain risk”?

At its heart, any uncertainty could potentially impact how well your supply chain works – sometimes negatively, sometimes even offering unexpected opportunities.

Think of supply chain risk management (SCRM) as your structured game plan. Specifically, it involves systematically:

Okay, here is the previously rewritten article, now reorganized with a clear H2, H3, and H4 structure for optimal readability and SEO hierarchy.

(Assumed H1 – Page Title)

Master Supply Chain Risk Management: Your Essential Guide to Building Business Resilience (2025 Update)

Sick of Supply Chain Surprises? Why Risk Management Isn’t Optional Anymore

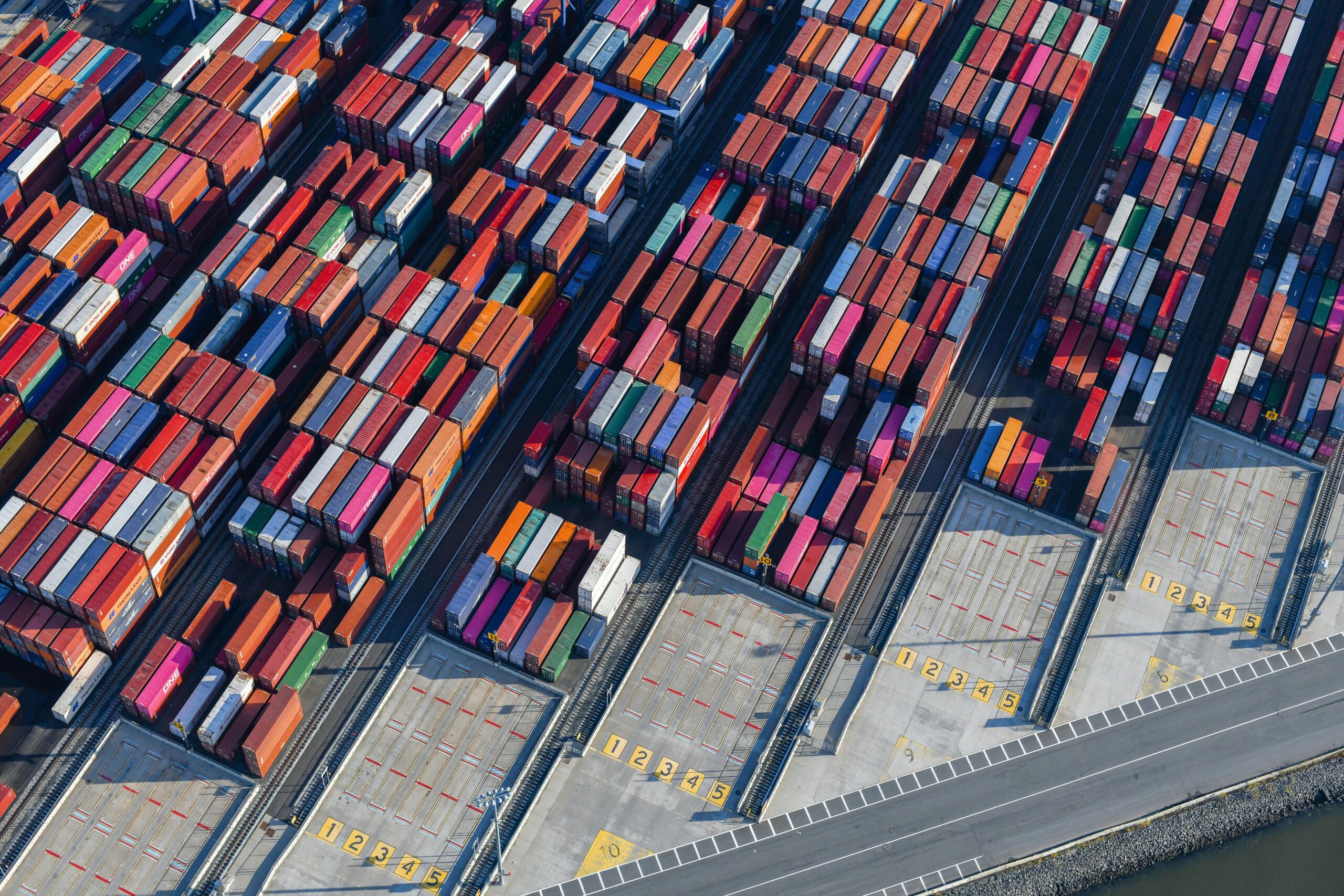

Let’s face it: in today’s fast-moving, interconnected world, supply chain disruptions aren’t a maybe; they’re a when. From unexpected natural disasters and shifting global politics to sudden supplier failures or crippling cyberattacks, countless things can throw a wrench into your smooth flow of goods, information, and money.

Consequently, having a solid supply chain risk management plan isn’t just a “nice-to-have” for big corporations. Instead, it’s absolutely essential for any business wanting to survive and thrive. If you want to protect your operations and keep your business running, understanding and managing risk is key.

What Exactly is Supply Chain Risk? Let’s Break It Down

So, what are we talking about when we say “supply chain risk”?

At its heart, it’s any uncertainty that could potentially impact how well your supply chain works – sometimes negatively, sometimes even offering unexpected opportunities.

Think of supply chain risk management (SCRM) as your structured game plan. Specifically, it involves systematically:

- Finding potential disruptions.

- Assessing how likely they are and how bad they could be.

- Figuring out the potential cost or impact.

- Finding potential disruptions.

- Assessing how likely they are and how bad they could be.

- Figuring out the potential cost or impact.

The ultimate goal? To control these risks or drastically reduce their negative effects. Ultimately, effective SCRM minimizes disruptions and is crucial for business continuity (keeping things running smoothly, no matter what).

Your 5-Step Action Plan for Effective Supply Chain Risk Management

Managing supply chain risk effectively isn’t random; it follows a clear, ongoing process. Here’s how you can tackle it step-by-step:

Step 1: Identify Your Potential Risks

First things first: you need to brainstorm and list all the potential risks that could affect your supply chain. Think broadly – consider both threats and hidden opportunities.

- How to do it: You need a wide view of your entire system. Use practical tools like team brainstorming, maintain a risk register (a running list), or conduct a SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) to cover internal and external factors.

- Crucially: Map out your entire supply chain. Understanding how each part connects and depends on others is vital for spotting potential weak points before they break.

Step 2: Assess and Prioritize Your Risks

How to Assess Risks

Evaluate each identified risk based on two critical factors:

- Potential Impact: If this risk happens, how much damage could it cause to your operations, finances, or reputation?

- Likelihood: Realistically, how likely is this specific risk to occur?

You can analyze these factors using simple descriptions (qualitative analysis) or complex numbers (quantitative analysis). By grading risks based on their impact and likelihood, you can prioritize where to focus your efforts first.

Common Categories of Supply Chain Risks

Risks often fall into familiar categories. Knowing these can help ensure you don’t miss anything:

- Strategic Risks: Long-term threats (e.g., damage to your brand, losing market share).

- Supply Risks: Problems with getting the goods/services you need (e.g., supplier bankruptcy, material shortages).

- Demand Risks: Uncertainty or big shifts in customer orders.

- Process Risks: Breakdowns in your own internal operations or procedures.

- Environmental Risks: External factors like natural disasters or changing government regulations.

- Hazard Risks: Direct loss of physical things you own (e.g., fire, theft of inventory).

- Financial Risks: Money-related issues like currency swings or economic downturns.

- Malfeasance Risks: Intentional wrongdoing like employee fraud or bribery.

- Litigation Risks: The threat of lawsuits.

Step 3: Develop Your Risk Response Strategy

For every significant risk you’ve prioritized, you now need a smart, cost-effective plan to address it. Essentially, you have a few main ways to respond:

- Avoid the Risk: Change your strategy or process entirely to eliminate the threat.

- Mitigate the Risk: Take specific actions to reduce the chance of the risk happening or lessen its impact if it does. This often involves creating detailed preventive action plans.

- Accept the Risk: Acknowledge the risk exists but decide to do nothing – usually reserved for risks with very low impact or probability.

- Transfer the Risk: Shift the responsibility or financial burden to a third party. Common examples include buying insurance or outsourcing a risky function.

- Furthermore, always prepare contingency plans (your Plan B or C). What steps will you take immediately if a risk materializes despite your prevention efforts?

Step 4: Put Your Plan into Action!

Planning is great, but action is what counts. This step involves actually implementing the response strategies you decided on. Naturally, this includes assigning the necessary people, budget, and resources to make the plans happen.

Step 5: Continuously Monitor and Adjust

Supply chain risk management is definitely not a one-and-done task. It’s an ongoing cycle.

- Therefore, you must constantly monitor the risks you’ve identified.

- Keep an eye out for new, emerging threats in the market or world.

- Regularly review and update your risk register and response plans. Ask yourself: Are our actions working? What new information do we have? Does our strategy need tweaking? Crucially, adapting to change is key.

Keys to Success: Planning, Collaboration, and Culture

Following the steps is crucial, but truly mastering supply chain risk management also involves embedding the right approach and mindset into your operations.

Why Planning and Teamwork are Your Secret Weapons

Having a formal, written risk management plan makes a huge difference. It ensures your approach is proactive, consistent, and clear to everyone involved. This plan should detail how your organization will identify, categorize, assess, and respond to risks.

However, in today’s incredibly complex global supply chains, you simply can’t manage risk effectively in a bubble. Collaboration is non-negotiable.

Working closely and sharing information with your supply chain partners (suppliers, logistics providers, distributors, etc.) is essential for building a truly resilient network. Specifically, this means:

- Establishing clear, open communication channels.

- Developing joint contingency plans for shared risks.

- Ensuring every partner understands their role and responsibility in managing potential disruptions.

Build More Than a Supply Chain – Build a Culture of Resilience

Ultimately, investing time and effort in robust supply chain risk management does more than just prevent problems. It fosters a culture of resilience throughout your organization and its entire network.

By actively identifying, assessing, and responding to potential disruptions before they become crises, your business can:

- Minimize the negative impact of unforeseen events.

- Maintain operational continuity (keep things running).

- Protect your valuable brand reputation.

- Gain a significant competitive advantage.

In conclusion, don’t view risk management as a burden. Embrace it as a continuous, integrated, and vital part of your everyday supply chain operations. It’s your key to navigating uncertainty, building a stronger business, and creating a truly successful and resilient supply chain fit for today’s world (and tomorrow’s!).