In today’s dynamic global economy, supply chains are generating an unprecedented volume, velocity, and variety of data. From real-time sales figures and detailed supplier performance metrics to granular transportation updates, the sheer flood of information can often feel overwhelming. Yet, within this “data overload” lies immense potential for unparalleled strategic insight and significant value creation. The ultimate key to transforming this raw data into actionable intelligence? Advanced supply chain analytics.

The Foundation: Beyond Basic Visibility

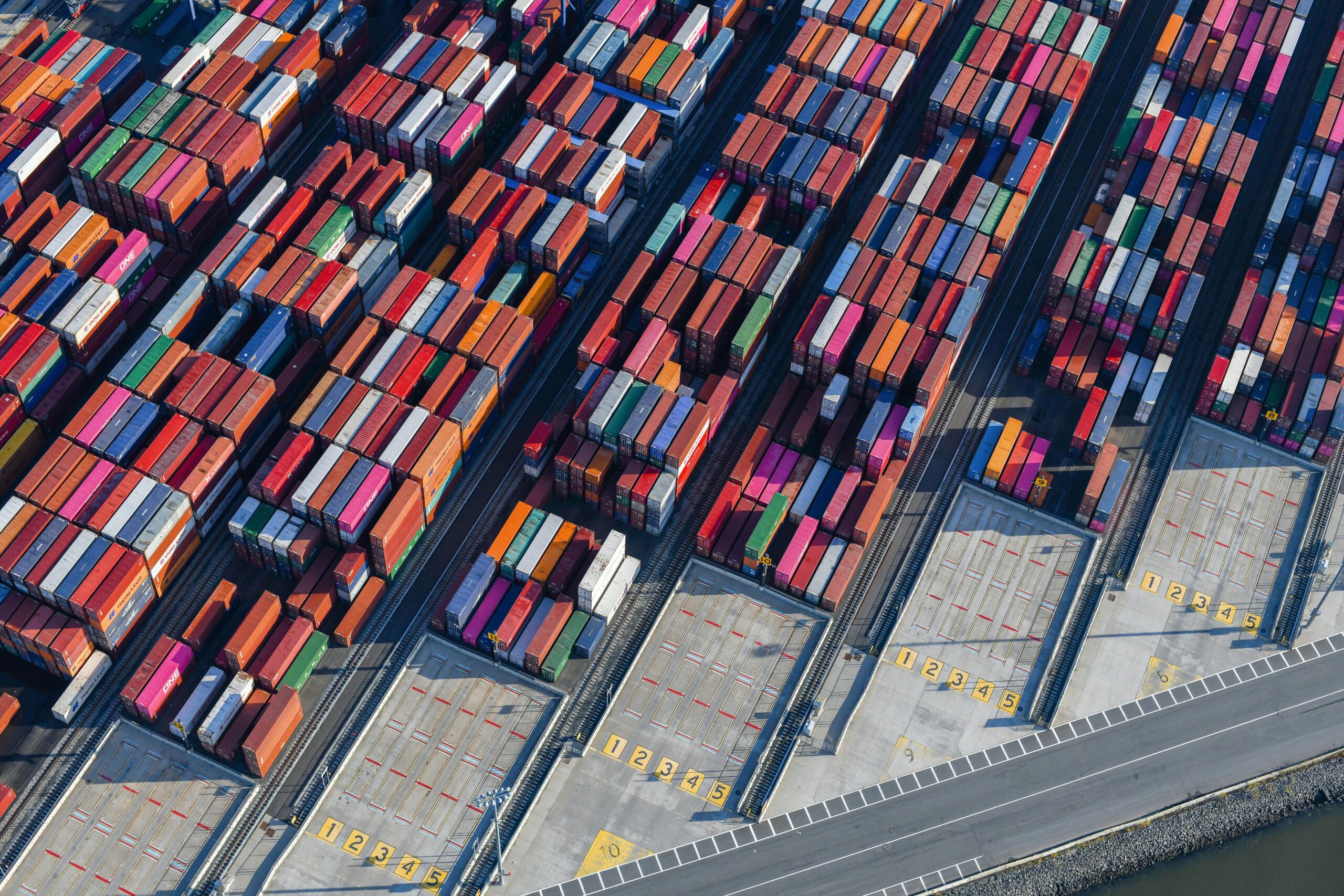

Many organizations acknowledge the critical importance of supply chain visibility—the ability to share information seamlessly across the entire chain, fostering transparency among all partners. This foundational step is essential, allowing managers to “see” what’s happening at any given moment, whether it’s inbound or outbound shipments, in-transit inventory, or exceptions to expected deliveries. Technologies such as Automatic Identification and Data Capture (AIDC) and integrated logistics information systems are crucial here, automating the tracking of goods and freeing up human resources to focus on physical movement and problem-solving.

However, true strategic insight transcends mere visibility. It demands a sophisticated process of transforming raw data into meaningful information, and subsequently, into actionable knowledge. This is precisely where advanced analytics steps in, empowering companies to:

- Identify potential problems before they escalate into costly disruptions.

- Optimize resource allocation across the entire network.

- Foster deeper, more proactive collaboration across the extended supply chain.

Predictive Power: Forecasting and Beyond

At the heart of leveraging supply chain data analytics is the transformative ability to predict future trends and events with greater accuracy. While traditional forecasting often relies solely on historical averages, advanced analytical methods incorporate a wider, more dynamic range of influencing factors:

- Time-Series Forecasting: This widely used quantitative method projects historical data trends into the future. Techniques such as simple moving averages, weighted moving averages, and exponential smoothing are commonly employed for short- to medium-term predictions. For products with inherent seasonality, it’s crucial to deseasonalize the data before forecasting and then reseasonalize it afterward to ensure accuracy.

- Associative Forecasting (Causal/Regression): This powerful method predicts a dependent variable (like future sales) by examining its relationship with one or more independent variables (such as leading economic indicators, marketing spend, or even weather patterns). It’s particularly valuable for long-term forecasting and at an aggregate level, as it aims to understand the underlying drivers of demand. For example, a roofing company might more accurately predict sales based on prior months’ housing starts rather than just past sales.

- Demand Sensing and Shaping: Advanced analytics enables organizations to detect near real-time shifts in consumer demand (known as “demand sensing”). With this agile insight, businesses can then proactively alter demand plans to reflect the new information, effectively “shaping” demand to meet supply or adjust inventory.

- Predictive Maintenance: By leveraging the power of Artificial Intelligence (AI) and Machine Learning (ML), predictive analytics can forecast equipment maintenance needs before a breakdown occurs. This proactive approach significantly reduces excess parts inventory, avoids costly downtime, and ensures operational continuity.

These sophisticated predictive capabilities are pivotal for transitioning from a traditional “push” system (driven by static forecasts) to a highly responsive “pull” system (driven by actual demand). By providing real-time point-of-sale (POS) data across the entire supply chain, advanced analytics dramatically reduces phenomena like the notorious bullwhip effect.

Optimization in Action: Strategic and Operational Impact

Advanced analytics provides powerful tools for optimizing various critical aspects of the supply chain, yielding significant benefits both strategically and operationally:

- Logistics Optimization: Modern Transportation Management Systems (TMS) utilize advanced analytical capabilities for everything from intelligent shipment planning and optimal carrier selection to efficient load matching. This ensures the most efficient routes, maximized cargo capacity, and substantial reductions in transportation costs. Web-based TMS interfaces further enhance this by providing real-time updates on shipment status, facilitating proactive planning, and quick adjustments.

- Warehouse Management: Sophisticated Warehouse Management Systems (WMS) deploy algorithms to optimize storage locations, facilitate efficient cross-docking operations, enhance real-time inventory control, and streamline order selection processes. The result is a significant boost in operational efficiency and a dramatic reduction in errors.

- Inventory Management: Methodologies like Demand-Driven Material Requirements Planning (DDMRP) dynamically adjust buffer inventories and strategically position them throughout the network. This approach minimizes risk while maximizing return on investment by explicitly accounting for demand and supply variability, ensuring products are available when and where needed.

- Sourcing and Supplier Management: Spend analysis, a comprehensive review of all organizational purchases, helps identify categories ripe for optimization and rationalizing the supplier base. Furthermore, Supplier Relationship Management (SRM) systems leverage analytics for strategic sourcing, rigorous performance measurement, and in-depth contract analysis. These systems provide a holistic, global view of purchasing activities, revealing hidden cost-saving opportunities and improving supplier collaboration.

- Network Design: Operations Research (OR) and network modeling employ sophisticated mathematical models, statistical analysis, simulation, and optimization techniques. Their goal is to identify the optimal number and strategic location of suppliers, manufacturing facilities, warehouses, and retail outlets. This ensures the supply chain infrastructure is perfectly aligned with overarching strategic goals, whether it’s minimizing costs, maximizing responsiveness, or improving sustainability.

- Process Improvement: Tools such as Value Stream Mapping (VSM) visually represent the flow of materials and information throughout a process. By clearly identifying wasteful or non-value-added activities, VSM enables organizations to streamline processes and enhance efficiency throughout their entire supply chain.

The Tools for Insight: Dashboards and Integrated Systems

To make these powerful analytical insights accessible and truly actionable, organizations rely on robust integrated information systems and intuitive reporting tools:

- Dashboards: These dynamic, easy-to-read management tools seamlessly combine business intelligence and data integration. They provide customized, near real-time views of key performance indicators (KPIs), instantly highlighting exceptions that require immediate attention. By making significant changes immediately apparent, dashboards enable swift and informed decision-making.

- Enterprise Resources Planning (ERP) Systems: Serving as the technological backbone of many businesses, ERP systems standardize critical business processes and provide extensive data repositories for comprehensive planning and control. Modern ERP versions extend connectivity across supply chain partners, transforming raw data into valuable business knowledge.

- Advanced Planning and Scheduling (APS) Systems: Functioning as an intelligent intermediary between ERP systems, APS systems utilize sophisticated analytical tools, including modeling and simulation. They optimize complex production, distribution, and inventory decisions at strategic, tactical, and operational levels. APS systems are crucial for supporting Available-to-Promise (ATP) and Capable-to-Promise (CTP) decisions, ensuring highly reliable delivery dates for customers.

- Supply Chain Event Management (SCEM): SCEM software is designed to actively monitor and flag specific supply chain events, triggering alerts or automated actions. It provides “active visibility” by continuously monitoring events, measuring performance against key performance indicators (KPIs), notifying decision-makers of critical exceptions, and even simulating the potential impacts of disruptions. This proactive approach helps organizations anticipate and avoid costly consequences.

- Customer Relationship Management (CRM): While primarily focused on customer interactions, CRM systems consolidate vast amounts of customer data into customer data warehouses. This wealth of information is invaluable for strategic marketing initiatives, new product development, efficient channel management, and boosting sales productivity. By supporting loyalty campaigns and personalized promotions, CRM ensures that demand signals are clearly understood and integrated into supply chain planning.

Conclusion: Embracing the Intelligent Supply Chain

The journey from overwhelming data overload to clear, strategic insight is an ongoing process that demands careful planning and meticulous execution. It extends beyond merely implementing advanced technology; it critically involves ensuring impeccable data integrity, fostering a culture of collaboration across departments and partners, and meticulously aligning all IT investments with the organization’s overarching strategies and supply chain objectives.

By wholeheartedly embracing advanced supply chain analytics, organizations can build truly “intelligent supply chains.” These sophisticated networks seamlessly integrate cutting-edge technologies, such as the Internet of Things (IoT), blockchain, and machine learning, to achieve unparalleled end-to-end visibility, exceptional agility, and profound resilience. This strategic shift empowers businesses to react swiftly and decisively to market changes, continuously optimize operations, significantly reduce costs, and ultimately, unlock immense value, ensuring they remain competitive and thrive in the ever-evolving global landscape.