As supply chain professionals, we constantly navigate a landscape of emerging technologies, each promising a revolutionary transformation. From AI to Blockchain, discerning genuine breakthroughs from fleeting trends can be challenging. One term that has firmly moved beyond mere hype is “Digital Twin.” While the concept of a precise virtual replica might sound futuristic, its application in supply chain management is rapidly maturing from a theoretical ideal to a powerful, practical tool that enables proactive management and delivers significant, tangible value.

The evolution of supply chains towards greater maturity and integration is undeniably driven by technology that fosters end-to-end connectivity and visibility. Capabilities such as real-time data utilization, advanced analytics, and sophisticated simulation are now essential for enhanced decision-making and operational efficiency. It’s precisely within this advanced technological context that the Supply Chain Digital Twin emerges as a logical and increasingly indispensable application of these combined capabilities.

What Exactly is a Supply Chain Digital Twin?

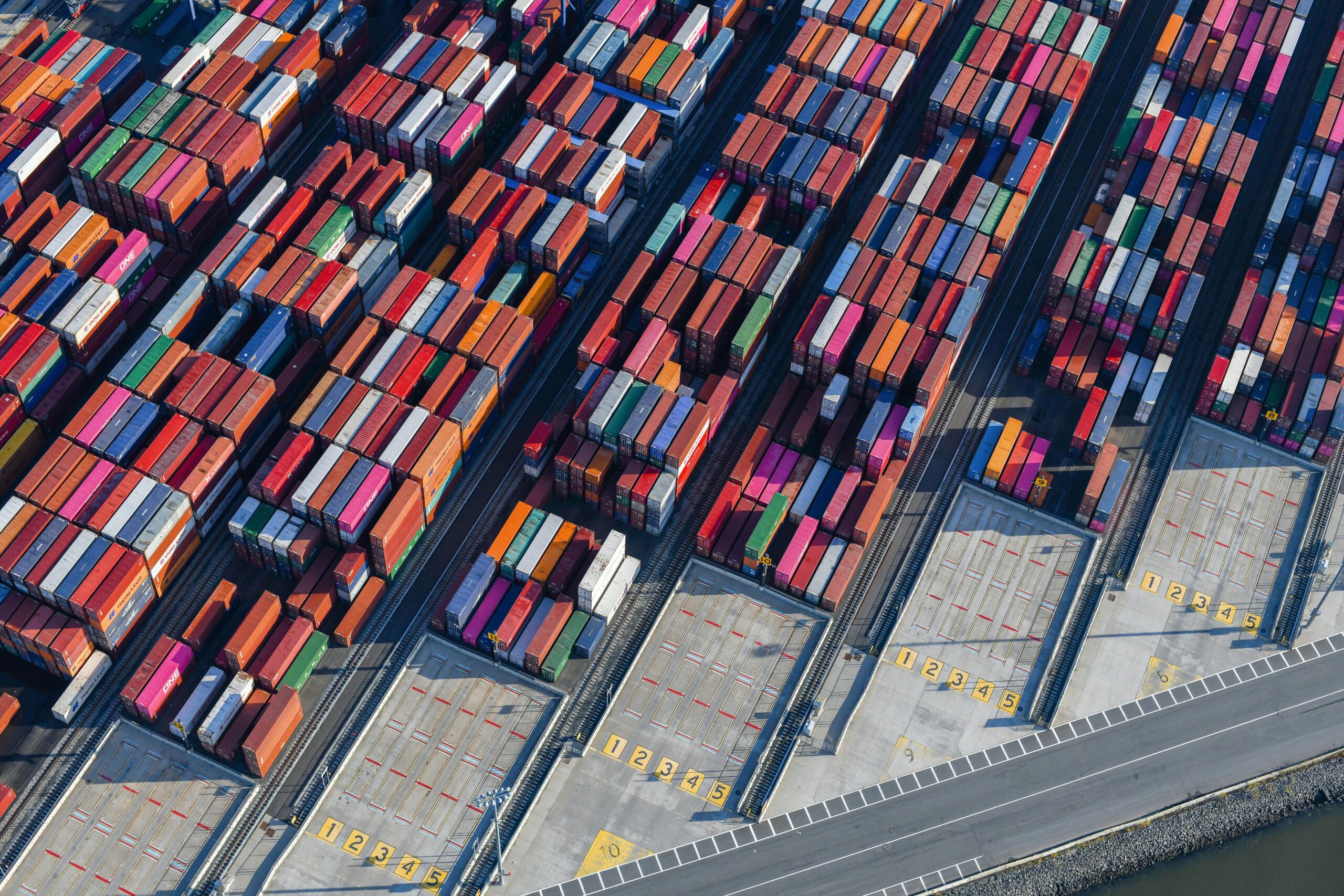

While the term “digital twin” can be applied at various scales – from a single piece of equipment to an entire manufacturing plant – a Supply Chain Digital Twin represents a dynamic, virtual replica of your complete physical supply chain network. This includes its processes, information flows, financial aspects, and potentially its key assets. Critically, this digital model is continuously updated with real-time, or near real-time, data from diverse sources across the physical Supply Chain.

Think of it as a sophisticated, living model that far surpasses static simulations or simple data dashboards. While traditional simulation allows you to model hypothetical “what-if” scenarios based on historical or assumed data, and dashboards typically provide a snapshot of current or past performance, a Digital Twin is intrinsically linked to the real-world operations. It ingests continuous data streams covering everything from incoming customer orders and current inventory levels across all nodes to in-transit shipment locations, supplier operational status, and even external factors like weather patterns or geopolitical events. This constant, multifaceted data flow enables the Digital Twin to accurately mirror the current state and behavior of the physical supply chain with remarkable fidelity.

Drawing an analogy, intelligent asset management (IAM) often involves creating a “digital twin” of an industrial asset, allowing its performance and condition to be constantly visible and analyzed for continuous improvement. A Supply Chain Digital Twin scales this concept, aiming to create this same level of dynamic, real-time visibility and interactive modeling for the entire network. This facilitates a holistic view and enables integrated, synchronized decision-making across multiple echelons, functions, and partner organizations.

The Breakthrough: Enabling Truly Proactive Management

The transformative power of a Supply Chain Digital Twin lies in its ability to shift operations from reactive problem-solving to genuinely proactive, predictive, and even prescriptive management. By providing a continuously updated, comprehensive, and interactive model of the supply chain, it empowers professionals to analyze potential future scenarios, predict emergent issues before they escalate, and optimize performance before disruptions or inefficiencies take root in the physical world.

Here are a few compelling use cases that highlight this breakthrough:

- Predictive Disruption Response and Enhanced Resilience: Modern supply chains face unprecedented risks, including natural disasters, geopolitical instability, supplier bankruptcies, and sharp demand volatility. A Digital Twin, fueled by real-time data and leveraging predictive analytics, can model the cascading impact of a potential disruption as it begins to unfold, or even before it fully materializes. For instance, if a key supplier’s region shows early warning signs of a labor strike, the Digital Twin can immediately simulate and quantify the impact on specific orders, production schedules, and downstream customers. This foresight allows managers to proactively explore alternative sourcing options, pre-emptively re-route shipments, or adjust production plans and inventory allocations before the disruption peaks. This significantly bolsters supply chain resilience – the crucial ability to anticipate, withstand, adapt to, and recover swiftly from disruptions.

- Dynamic Network Design and Strategic Optimization: Supply chain network configuration is a critical strategic decision, encompassing the optimal location and capacity of facilities, transportation lane design, and determining the flow path. A Digital Twin provides a robust, dynamic platform for continuous network optimization. Instead of relying on periodic, static models, it can run “what-if” scenarios using current, real-world operational data to evaluate the impact of potential strategic or tactical changes, such as adding a new distribution center, shifting production between plants, adopting new transportation modes, or changing inventory policies. This dynamic modeling capability ensures that network design remains aligned with evolving business objectives, such as cost reduction, service level improvement, or sustainability targets.

- Intelligent Inventory Planning and Optimization: Inventory represents a substantial capital investment and a critical balancing act between service levels and costs. The challenge is to maintain sufficient stock to meet demand while minimizing disruptions, holding costs, and obsolescence. A Digital Twin, offering real-time visibility into demand patterns (often far beyond simple forecasts) and precise inventory levels across every node in the network, provides highly accurate insights for optimizing inventory positioning, buffer sizing, and replenishment strategies. By modeling the end-to-end flow of goods and responding to actual demand signals and supply variabilities, it can help mitigate the bullwhip effect, leading to reduced holding costs, improved fill rates, and minimized stockouts. This often incorporates or enhances existing inventory optimization software capabilities.

These applications translate into tangible benefits, including significantly improved responsiveness to market changes, increased operational efficiency through waste reduction, better resource utilization, enhanced risk mitigation, business continuity, faster and higher-quality decision-making, and ultimately, the creation of sustainable net value for all stakeholders.

Making it Real: Practical Considerations for Implementation

Implementing a comprehensive Supply Chain Digital Twin is a significant endeavor. It relies heavily on a robust technological foundation and requires addressing several practical challenges.

- Enabling Technologies: At its core, a Digital Twin thrives on vast quantities of accurate, timely data, often captured by sensors and devices across the physical supply chain – the Internet of Things (IoT). This raw data is then ingested, processed, and analyzed using sophisticated Data Analytics platforms and techniques. To unlock predictive and prescriptive capabilities, Artificial Intelligence (AI) and Machine Learning (ML) algorithms are essential, enabling the system to identify complex patterns, forecast future outcomes, and recommend optimal actions. Supply Chain Control Towers, which offer centralized visibility and decision support, can be seen as foundational elements or integrated components of a broader Digital Twin strategy. Furthermore, technologies like Blockchain are being explored to provide secure, transparent, and immutable records for asset provenance, chain of custody, and critical shipment data.

- Adoption Challenges: Despite the compelling potential, organizations face hurdles. A primary challenge is data: achieving the necessary quality, completeness, granularity, and timeliness of data is paramount. Integrating data from disparate internal enterprise systems (like ERP, WMS, TMS) and, crucially, from external partners (suppliers, logistics providers, customers) can be immensely complex. The complexity of building, validating, and maintaining a dynamic model that accurately represents the entire supply chain network is significant and demands specialized expertise in data science, supply chain modeling, and software engineering. Finally, the cost associated with the required technology infrastructure (IoT sensors, data platforms, AI/ML software, cloud services) and the recruitment or development of skilled personnel to build and manage the twin can be substantial. Beyond technology and cost, organizations must proactively manage the human element, including addressing potential resistance to change from individuals accustomed to traditional processes and decision-making methods.

Addressing these challenges effectively requires meticulous planning, a phased implementation approach (often starting with a digital twin for a specific critical process, region, or product line), strong executive sponsorship, and a relentless focus on robust data governance and comprehensive change management.

Future Outlook and Moving Forward

The vision of a fully realized, autonomous, end-to-end Supply Chain Digital Twin is still advancing, but the foundational technologies are maturing at an accelerated pace. As organizations globally continue to embrace digital transformation, thereby improving data connectivity, analytical capabilities, and systems integration, the feasibility and value proposition of building and leveraging Digital Twins will only increase.

For supply chain professionals, developing a clear understanding of Digital Twin capabilities and potential is no longer optional – it’s becoming crucial. This technology represents a paradigm shift toward truly proactive, data-driven, and intelligent decision-making, which can confer a substantial and sustainable competitive advantage in an increasingly complex world.

Ready to explore the potential of Digital Twins for your supply chain? Begin by assessing your organization’s current data visibility, integration maturity, and analytical capabilities. Identify which critical processes or key performance indicators could benefit most from real-time modeling, predictive insights, and optimized, proactive interventions. The journey to a Digital Twin is an evolution, but the rewards promise to redefine supply chain excellence.