In an increasingly interconnected world, expanding the supply chain beyond domestic borders can unlock significant opportunities for growth, access to new markets, and cost optimization. However, navigating the complexities of global trade requires careful planning and a deep understanding of various critical factors. This blog post will explore the key considerations for building and managing a successful international supply chain.

Designing the Global Supply Chain Network:

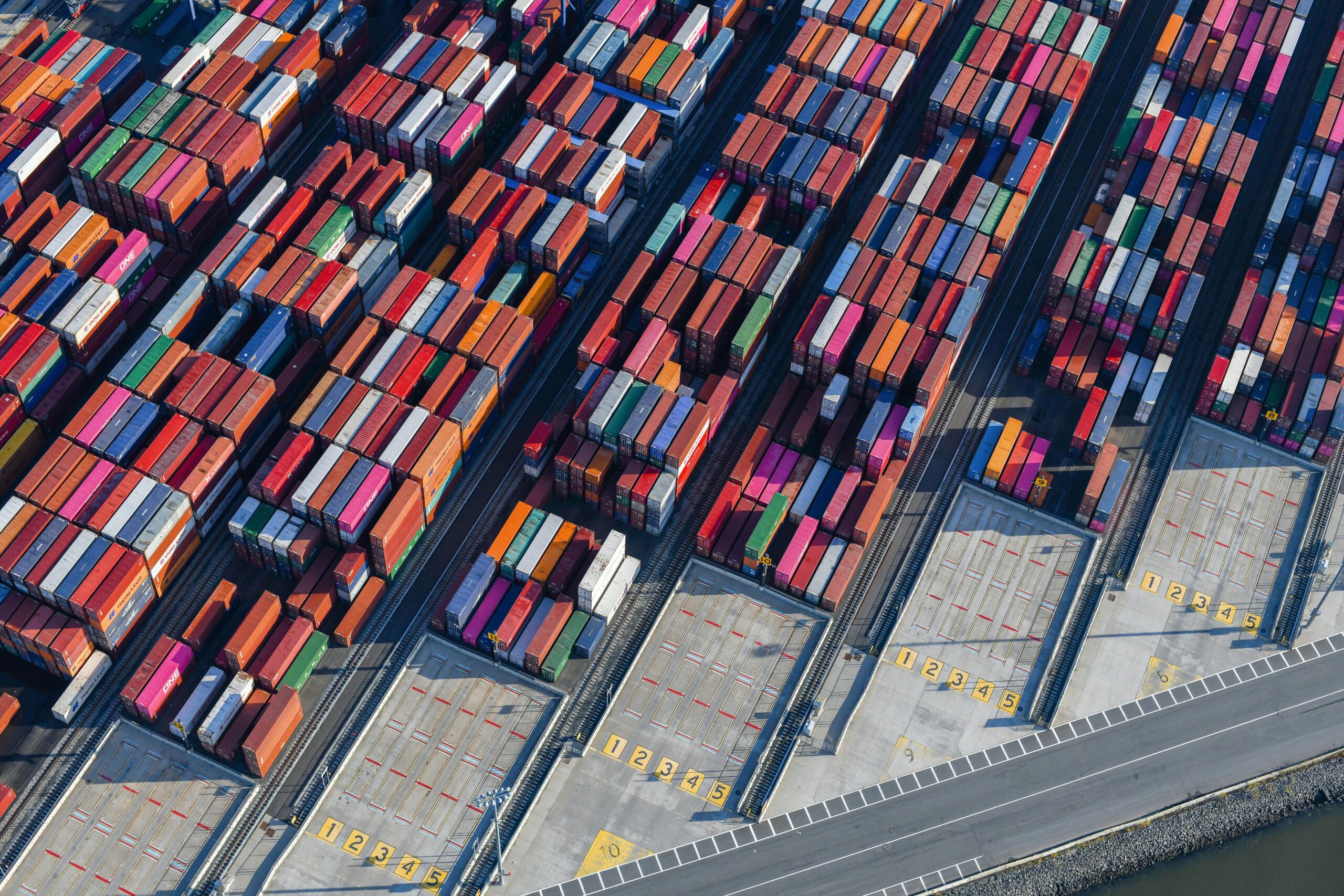

The foundation of a successful international supply chain lies in its design. This involves strategically aligning the supply chain with the overall organizational strategy and business requirements. Key decisions include determining whether the supply chain should prioritize efficiency or responsiveness based on product markets. The organization will also need to develop an IT strategy and choose the right tools to ensure end-to-end connectivity and visibility across the global network. Master data management is crucial for maintaining timely and accurate information. Furthermore, understanding local infrastructure issues in the countries operating in, such as port facilities, airports, and highway conditions, is vital for smooth logistics.

Strategic Sourcing in a Global Marketplace:

Sourcing products and services internationally presents both opportunities and challenges. A critical first step is a make-versus-buy analysis to determine which activities are best kept in-house and which should be outsourced. When sourcing globally, aligning sourcing activities with demand is paramount. Developing category strategies helps manage different types of suppliers effectively. Supplier selection is a crucial process that requires thorough due diligence. The organization will need to master best practices for operating in a global market, including identifying and researching strategic partners. Negotiating long-term contracts and understanding different contract types are also essential. Consider the total cost of ownership (TCO) when making sourcing decisions.

Mastering International Logistics and Transportation:

Logistics is a critical function in international supply chain management, encompassing the forward and reverse movement of goods. The organization will need to understand the advantages and disadvantages of various transportation modes and select the appropriate mode based on factors such as cost, speed, and the nature of the goods. Be prepared to manage complex export packaging requirements and potentially work with third-party logistics (3PLs) or fourth-party logistics (4PLs). Efficiently dealing with customs during import and export is vital. This often involves understanding the roles of import/export intermediaries like customs house brokers.

Navigating the Labyrinth of Trade Regulations and Compliance:

Operating globally means adhering to a complex web of import/export regulations and related standards. The organization must be aware of security concerns, including the risk of loss, and comply with all import and export requirements. Participation in voluntary security partnerships like C-TPAT in the U.S. can offer benefits such as fewer inspections. Understanding customs regulations related to prohibited goods and documentation is crucial. Furthermore, be mindful of the impact that differences in international, country, and local labor laws can have on the global supply chain. The Harmonized Tariff Schedule is a key tool used in import and export transactions. Familiarize the organization with the potential impact of free trade zones and trading blocs. Understanding Incoterms® trade terms is essential for clarifying cost responsibilities and the transfer of risk between buyer and seller in foreign trade contracts

Mitigating Risks in a Globalized World:

International supply chains are inherently more susceptible to a broader range of risks. Being proactive and resilient in identifying, assessing, and responding to these risks is vital. Develop a comprehensive risk management strategy and plan, including specifying the organization’s risk tolerance. Typical supply chain risks include loss of goods, malfeasance, lawsuits, and intellectual property losses. Implementing an integrated approach, such as combining Failure Mode and Effect Analysis (FMEA) with a Supply Chain Risk Management Process (SCRMP), can provide valuable decision support for the supply chain design.

Building Strong Customer and Supplier Relationships Across Borders:

Managing customer and supplier relationships is critical for a cohesive global supply chain. Customer Relationship Management (CRM) methodologies help transform the supply chain into a system that delivers value to customers. Understanding customer data and segment wants and needs is fundamental. Similarly, Supplier Relationship Management (SRM) is essential for strategic sourcing. Cultivating a collaborative corporate mindset with alliance partners is key to long-term success. Effective communication, tailored to different audiences and cultural contexts, is paramount in international business.

Leveraging Technology and Data in the Global Operations:

Technology plays a pivotal role in managing the complexities of a global supply chain. Integrating IT and decision support systems into a competitive strategy is crucial. Utilizing automatic identification technologies like bar codes and RFID helps reduce data errors and increase information velocity. Content management e-commerce applications can help manage product information globally.

Embracing Sustainability in the International Supply Chain:

Increasingly, stakeholders expect global supply chains to be sustainable. Consider the triple bottom line of supply chain processes (economic, environmental, and social). Familiarize the organization with sustainability guidelines and standards such as the Global Reporting Initiative (GRI).

Conclusion:

Navigating global trade and managing an international supply chain requires a multifaceted approach. The organization can build a resilient and successful global operation by carefully considering supply chain design, strategic sourcing, international logistics, trade regulations, risk management, customer and supplier relationships, technology, and sustainability. Understanding these key considerations is not just about expanding the organization’s reach; it’s about building a strong foundation for long-term growth and competitive advantage in the global marketplace.