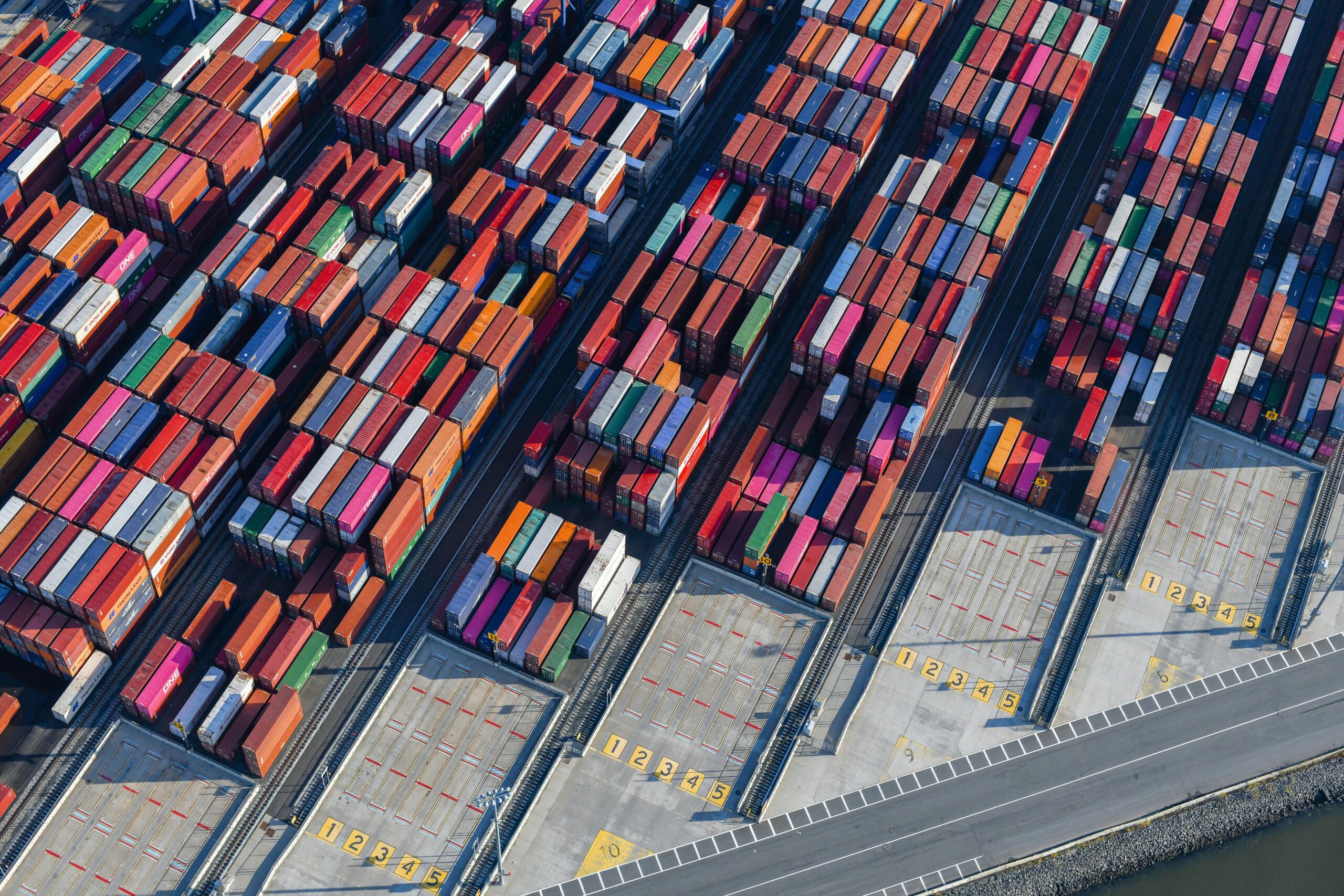

The global supply chain environment remains in a state of significant flux. As we navigate 2025, escalating geopolitical instability is not a future prediction – it is the present reality impacting businesses across every sector. From simmering conflicts and evolving trade policies to resource constraints and regulatory hurdles, supply chain and logistics leaders are confronting an increasingly volatile operational landscape. Merely reacting to these disruptions is insufficient; embedding supply chain resilience into core strategy is now fundamental for survival, competitiveness, and sustainable growth.

Decoding the Geopolitical Risk Matrix in 2025

Geopolitical events trigger tangible economic shifts, influence migration, reshape regional power balances, and send shockwaves directly through intricate global supply networks. The challenges we face in 2025 are complex and interconnected, placing sustained pressure on logistics operations:

- Trade Tensions and Policy Volatility: The Era of Predictable Global Trade Is Challenged. Ongoing and potential tariff disputes, as analyzed in the “Global Tariff War Analysis,” require proactive cost management and adaptive sourcing strategies. The uncertainty surrounding trade policies necessitates managing supply chains with the assumption of continuous disruption, rather than hoping for temporary reprieves. Consider the direct impact of tariffs on export-dependent sectors and the cascading cost increases from retaliatory measures – these require sophisticated navigation.

- Conflict & Regional Instability: Geopolitical flashpoints directly threaten logistics. Conflicts can damage critical infrastructure, such as ports, railways, and roads, as historical examples demonstrate. Current tensions, such as those affecting major maritime routes like the Red Sea, drastically alter global shipping flows, inflate costs, and necessitate urgent contingency planning.

- Regulatory Complexity: Evolving customs regulations, both regional (e.g., Middle East) and international, add layers of complexity to cross-border trade. This increases the administrative burden, heightens the risk of delays, and demands up-to-date compliance expertise.

- Climate and Environmental Pressures: While not solely geopolitical, climate change acts as a threat multiplier, increasing the frequency and severity of natural disasters that cause significant, often localized, disruptions to supply chains. Competition for resources, exacerbated by climate factors, also impacts raw material availability and pricing.

- Technological Interdependence & Vulnerability: Our increasingly interconnected supply chains rely heavily on technology. This creates vulnerabilities to cybersecurity threats, system failures, and targeted attacks that can paralyze operations.

- Public Health Crises: The recent pandemic served as a stark reminder of how unforeseen health events can trigger massive demand fluctuations, cripple production, and expose supply chain fragilities. Planning for such high-impact, low-probability events is now crucial.

From Resilience to Anti-Fragility: Building a Future-Proof Supply Chain

In this environment, the goal evolves beyond simple resilience (the ability to recover) towards anti-fragility – designing supply chains that can potentially strengthen from shocks and volatility. Achieving this requires a strategic mindset shift and the deliberate implementation of risk mitigation techniques. Based on leading industry insights, here are the critical strategies for 2025:

Actionable Strategies for Enhanced Supply Chain Performance:

1- Strategic Network Diversification:

- Reduce Single-Point Dependencies: Aggressively mitigate reliance on single countries, regions, or suppliers.

- Explore Alternative Markets & Sources: Actively identify and cultivate relationships in geographically diverse and politically stable locations. Consider the strategic merits of “friend-shoring” or “near-shoring.”

- Foster Regional & South-South Trade: Strengthen intra-regional partnerships and build deeper ties with emerging economies to diversify market access and reduce reliance on historically dominant, potentially volatile trade routes.

2- Harness Visibility & Technology:

- Invest in Real-Time Visibility: Implement technology platforms providing end-to-end supply chain transparency.

- Leverage Data Analytics: Utilize predictive analytics for demand forecasting, disruption modelling, and scenario planning to inform proactive decision-making. Knowing when to activate contingencies is key.

3- Embed Agility & Flexibility:

- Flexible Contractual Agreements: Build adaptability into supplier contracts.

- Develop Alternative Logistics Routes: Pre-plan and vet secondary or tertiary transportation options.

- Strategic Buffering (Where Appropriate): Utilize buffer stocks judiciously for critical components, considering the balance between inventory holding costs and disruption risks.

4- Institutionalize Risk Management & Contingency Planning:

- Conduct Rigorous Risk Assessments: Regularly identify and evaluate potential geopolitical, economic, and environmental threats specific to your supply chain.

- Develop & Test Contingency Plans: Create detailed, actionable plans for various disruption scenarios. Assign clear ownership, review, and update these plans frequently.

5- Master Customs & Compliance:

- Develop In-House or Partner Expertise: Ensure a deep understanding of tariff codes, rules of origin, and evolving customs regulations to manage duties effectively and identify potential savings, such as exemptions and duty deferral programs. Accurate classification is critical.

6- Proactive Financial & Commercial Management:

- Analyze Cost Impacts: Meticulously model the financial effects of tariffs, disruptions, and inflation on your cost structure and pricing.

- Engage in Strategic Negotiations: Foster open dialogue with suppliers and customers regarding cost-sharing and value engineering opportunities to mitigate financial pressures.

7- Leverage Logistical Hub Advantages:

- (Region-Specific): For businesses operating in or near major logistics hubs (like the GCC), capitalize on investments in infrastructure, digitalization, and port capacity to attract trade flows seeking reliable alternatives.

8- Stay Informed & Advocate:

- Continuous Monitoring: Closely track geopolitical developments, trade policy shifts, and regulatory changes.

- Industry Engagement: Participate in industry associations to stay informed, share best practices, and contribute to policy discussions that impact trade and logistics.

Conclusion: Thriving in the Age of Disruption

The challenges facing global supply chains in 2025 are substantial, but not insurmountable. Moving from a reactive footing to a proactive, resilience-focused strategy is no longer optional – it’s the defining characteristic of successful, enduring businesses. By strategically diversifying networks, embracing technology-driven visibility, building operational agility, and embedding robust risk management practices, organizations can not only navigate the turbulence but also potentially uncover competitive advantages in a rapidly transforming global trade order. The “new normal” demands adaptation; those who embrace it will lead the way.